News - 02.09.2021

Stencils And Their Ultimate Influence

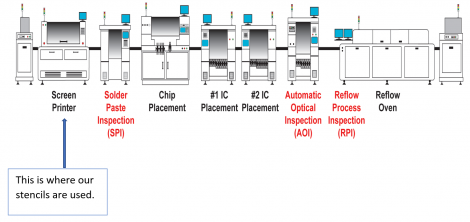

Why is the stencil so important? Stencil printing is the first step in the SMT assembly line and is the tool designated to apply the solder paste that will make every interconnection on the PCB

Ross Howard

Ross Howard

Stencils And Their Ultimate Influence

Datum have provided stainless steel to produce metal masks or solder stencils for the Surface Mount Technology (SMT) industry for over 20 years. SMT is a method for producing electronic circuit boards where components are mounted or placed directly onto the surface of Printed Circuit Boards (PCBs). During the past 20 years Datum have become the market leader in the supply chain to this industry because of our focus on the end application. Datum have developed their understanding to provide solutions to challenges throughout the production process.

Why is the stencil so important?

Stencil printing is the first step in the SMT assembly line. The stencil is a tool to apply the solder paste that will make every interconnection on the PCB and is often regarded as the most important element in the whole process.

The purpose of the stencil is to control position and size of the paste deposits on the PCB and can define the quality, productivity, and profitability of the SMT line.

Poor printing will cause:

- Defects due to poor quality solder joints

- Increased rework

- Rework and replacement

- Increased time and cost

Good printing will give:

- Reduced defects

- Improved throughput

- Reduced overall product cost

What have Datum done?

Datum examined the printing process and the influence that the stencil has. Some of the main challenges that have been addressed are:

Flatness – The stencil needs to remain flat after laser cutting (or etching). If the stencil is not flat it will cause misalignment or poor gasketing during printing, leading to defects on the PCB. Datum has ensured that their product specification gives an extremely tight tolerance on flatness of material. We have also implemented specific production methods to give a material with reduced internal stress, resulting in flatter material after cutting. This becomes more critical in areas of high-density apertures.

Thickness control – Volume of paste deposits are crucial to the design and efficacy of the PCB and the components that will be placed on the board. Previous substrates that were being used (some still being used) had a thickness tolerance of +/-10%. Datum have controlled their manufacturing process to give thickness tolerances as tight as +/-1%. These controls ensure that the manufacturers can be confident in what they should expect from the stencil.

Paste release and cut quality – Datum has a consistent and controlled material. Our substrates have a homogenous structure with minimal impurities. There are many influences over paste release and cut quality that are in control of the stencil producers. With the correct laser settings our material has demonstrated superior cut quality and produces smooth aperture walls for excellent paste release.

Continued development – Datum has developed numerous premium products that provide benefits to the industry. We continually look at providing value to the industry and tangible benefits to the end producers of PCBs.