News - 02.23.2021

Why Datum Produces Pre-Mounted Frames

There are many tensioning systems for solder stencils. The original and most widely trusted is the mesh mount frame.

Ross Howard

Ross Howard

Why Datum Produces Pre-Mounted Frames

There are many tensioning systems for solder stencils. The original and most widely trusted is the mesh mount frame.

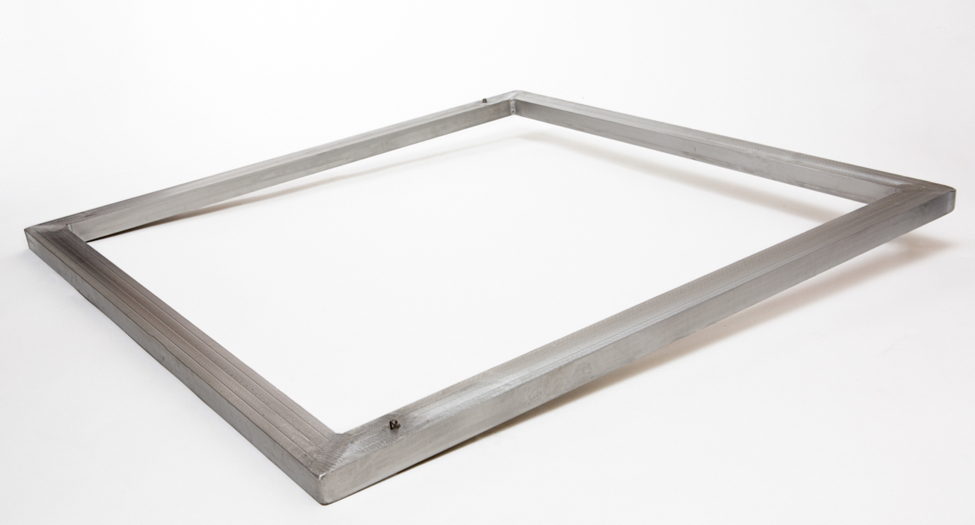

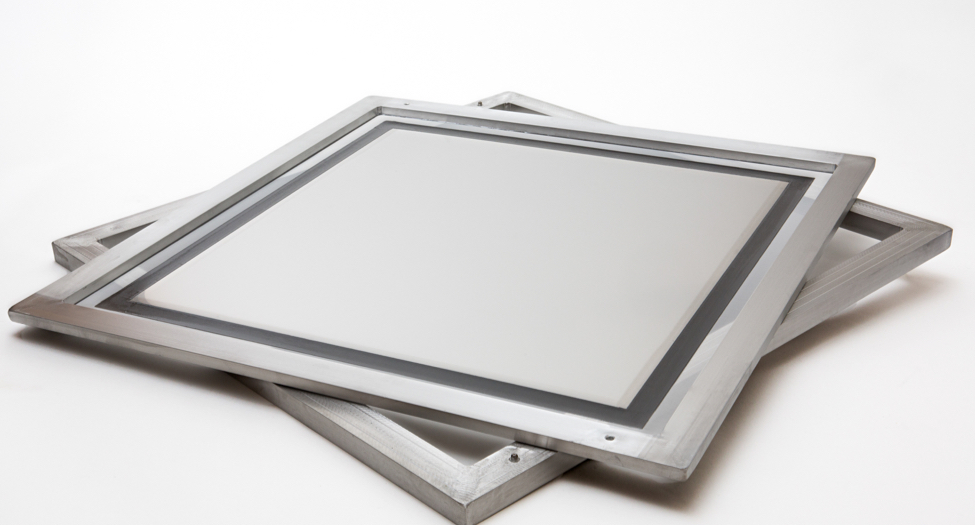

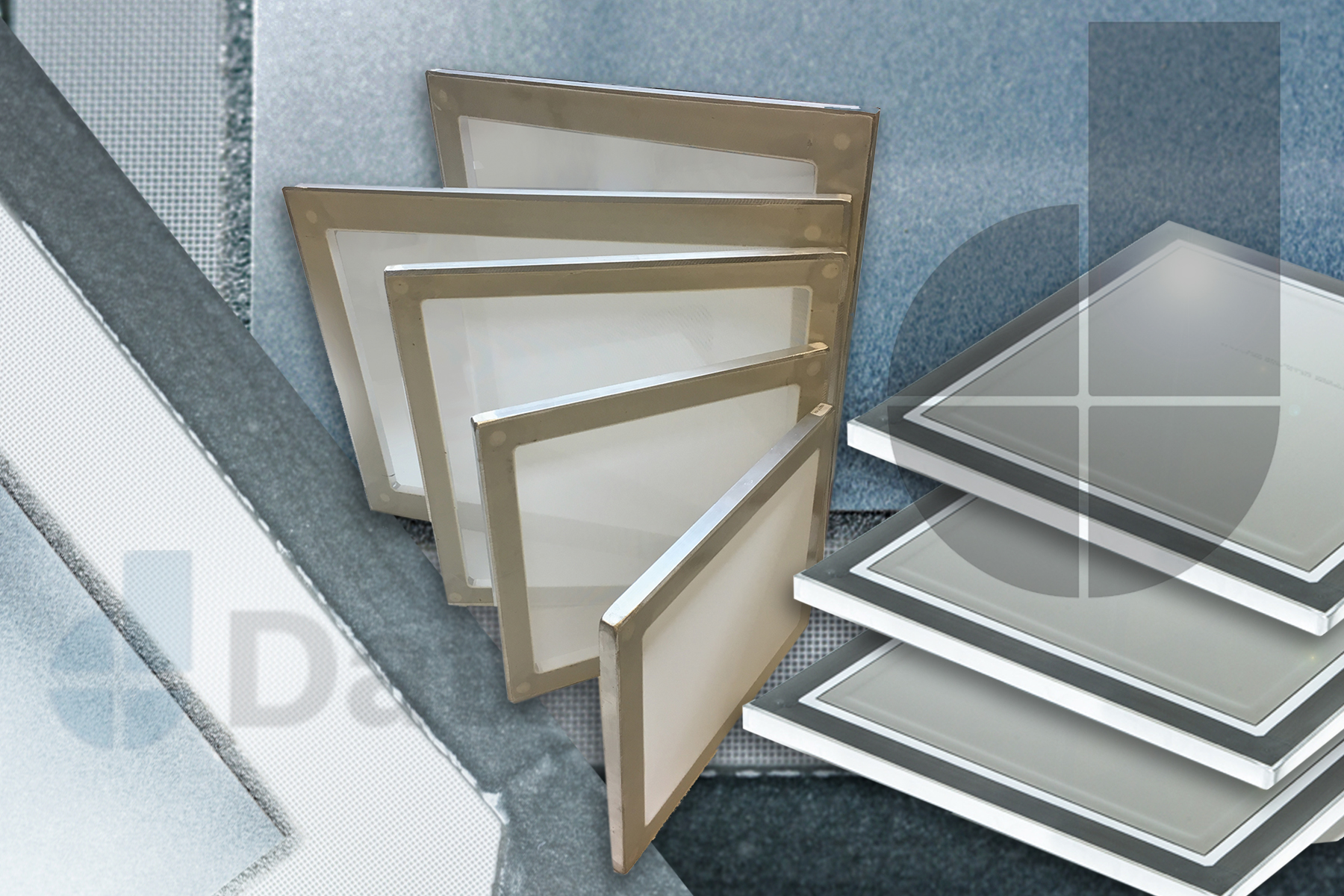

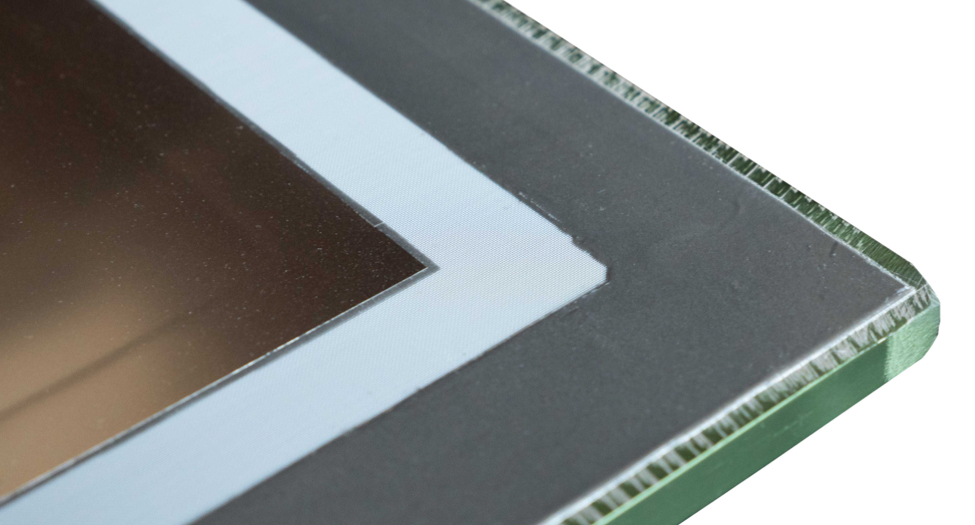

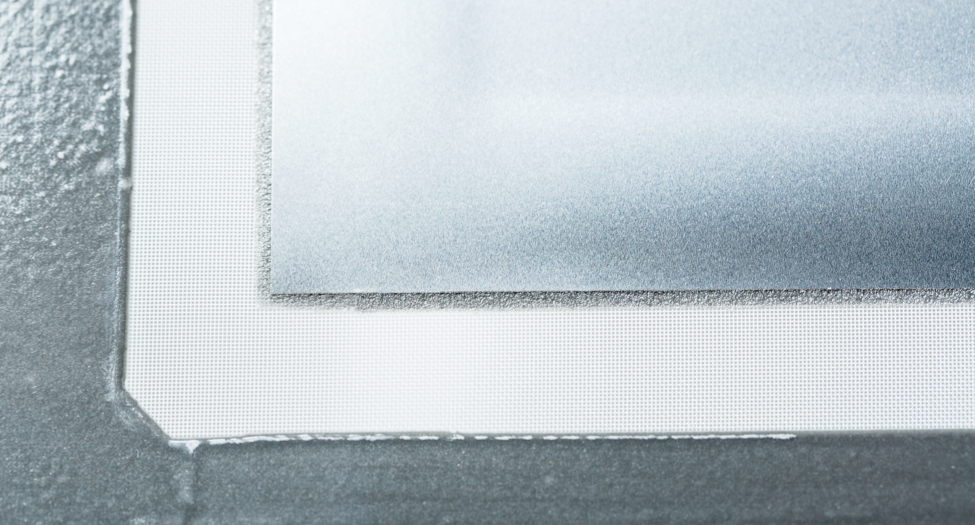

Datum supplies frames in various market standard and non-standard sizes. The frames are pre-meshed with polyester or stainless steel mesh that is tensioned onto the aluminum frame. The stencil substrate, usually Datum steel, is bonded to the polyester or steel mesh and the mesh is cut away to transfer the tension onto the steel sheet and pull it tight. This produces a consistently flat substrate so that an accurate stencil pattern can be cut.

For over 20 years, Datum has always focused on the benefits their products provide to the end application. The stainless steels, Datum PhD, Tension and Fine Grain, all originated from Datum with the focus on providing stencil manufacturers and printed circuit board (PCB) producers the best substrates for their stencil applications.

To continue adding value to the stencil and PCB industry, after developing the best stainless steel for stencils, Datum decided to offer pre-mounted frames.

Mounting stainless steel onto frames is a labour intensive process. Many stencil providers were carrying out this process in house and it was clear to Datum that PCB manufacturers were getting inconsistent products when purchasing stencils from different stencil houses. Datum always strives to provide the best products in everything we do and as we began to move the production of the mesh mounted frames in house this philosophy has continued. We continue to refine and develop the process to give the best results.

Datum now provides tens of thousands of pre-mounted frames each year into the stencil market across the world.

Consolidating the production of the mounted frames has allowed Datum to create an extremely consistent product. Having Datum supply pre-mounted frames takes an extremely labour intensive and time consuming process away from the stencil houses and allows them to focus on producing stencils.

Datum has also been able to create efficiencies in the production process that means manufacturing costs can be kept down whilst maintaining a consistent product.

Datum sees tremendous value in all of the processes we have implemented which allow stencil manufacturers and PCB producers the time to focus on their key strengths and produce the best circuit boards for their applications in the most efficient manner and be confident that the substrate will provide them with the quality base product that they expect.