EXPERTISE

EXPERTISE

Leaders and Innovators

With more than 25 years’ experience, Datum Alloys have been at the forefront of our industry, delivering tools and products to manufacturers, innovator’s, and technology developers.

01

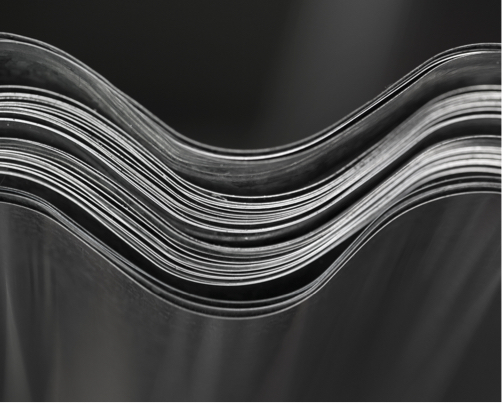

Precision

Our thickness controls and tolerances lead the industry. We are the only company to guarantee a 2% thickness tolerance on our advanced stainless-steel foils. We only supply the best performing materials and provide products with the highest degree of precision.

02

Efficiency

We offer the fastest delivery times in the industry and regularly ship on the same day. All orders are shipped within 48 hours and this is a metric we continue to invest in and improve on.

03

Guaranteed Performance

All Datum products are rigorously tested before coming to market, and this test data is available. Our suppliers are controlled by our strict purchasing specifications and audits. We test all incoming material and outgoing products to ensure they meet our standards, and we guarantee performance for our customers. We are ISO 9001:2015 certified.

MARKETS SERVED

MARKETS SERVED

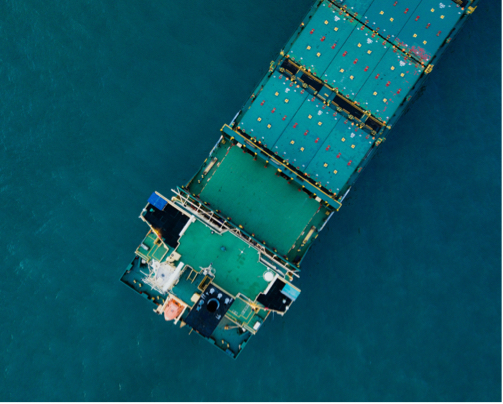

We are global leaders serving diverse markets

With facilities located in the UK, USA, and Singapore, Datum service customers globally and support regional and market needs wherever they are in the world. From mobile devices, healthcare technology to automobiles - Datum products have a diverse and wide customer base.

We help companies launch their innovations. Our tools, materials, products, and expertise help get other companies’ products to market.

The 3D tools we produce have microscale features with single micron tolerances. These tools can be made from stainless steel, titanium, and molybdenum.

Our innovations and micro tooling help make devices such as implantable pacemakers and defibrillators smaller and less invasive.

Our stencil materials set the standard for tool life, repeatability, and yields. Our customers have seen efficiency improve by up to 38% after switching to our materials.