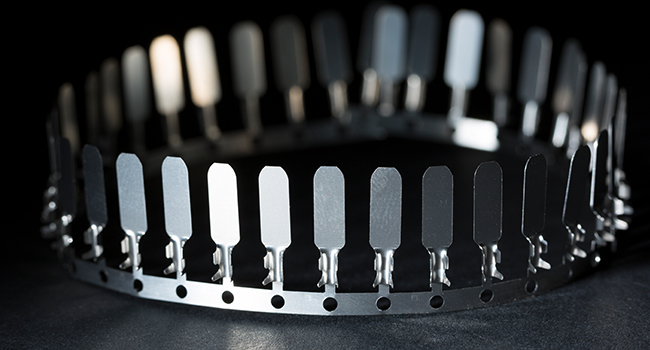

Nickel Strip

Datum offers a wide range of standard and custom battery connectors, battery crimps and battery tags in nickel plated steel, nickel plated copper, nickel solder tabs and pure nickel strips to suit your requirements and application. We produce all our strips and tags in-house. They are cut to order with our specialized slitting and cutting equipment. This enables us to deliver high-quality standard and custom-size tags at competitive prices with short lead times.

Custom nickel strips are becoming increasingly popular as miniaturization and power electronics drive specialized tag shapes, formats and load requirements. We can specialty etch or stamp custom-shaped tags, and provide Design For Manufacture (DFM) input to ensure high-yielding and repeatable production processes.

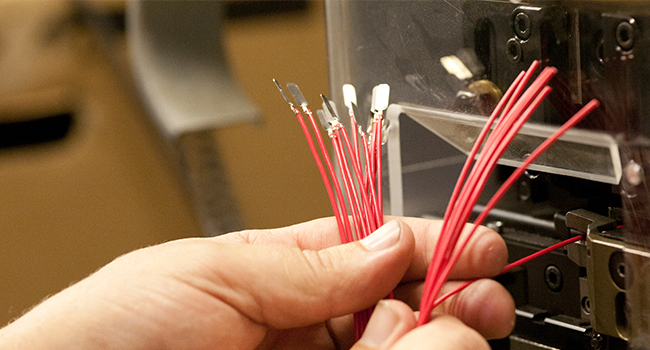

Datum manufacture custom battery connectors to your specifications from coil or sheet. We also offer a comprehensive crimping service via a trusted third party with the capability to crimp to any pre-crimped or preassembled wire.

- Available wire sizes: 20-26 AWG, Standard 7/0.2mm, others available upon request

- Crimp dimensions: 11mm spade and 16mm in length

- Material: Nickel plated stainless steel

Get in touch with our team on:

+44 (0) 1548 855 900 (UK & Europe)

+1 607 239 6274 (US)

+65 3157 0394 (Singapore)

Nickel Strip

Product Inquiry

Login

Please enter your name and email address to login.

Please contact us if you do not have an account

Customer Name

Order History

| Product | Unit Price | Quantity | Total |

|---|

Back to Order List

Customer Name

Order Details

| null | $0.00 |

|---|---|

| Quantity: 0 |

Total

| Taxes | $0.00 |

|---|---|

| Total | $0.00 |

Repeat Order

You can change the quantity and address on next page.

Repeat Order

Confirm Order

Please enter your name, email and confirm your shipping address to complete your order of:

Details

Details

We use Nickel 200/201 grade, which conforms to the ASTM B162 standard. It’s commercially pure (99.6% and higher) with good mechanical properties, and is resistant to a range of corrosive media. Our nickel strip and tags make excellent battery connectors because they have a low electrical resistance.

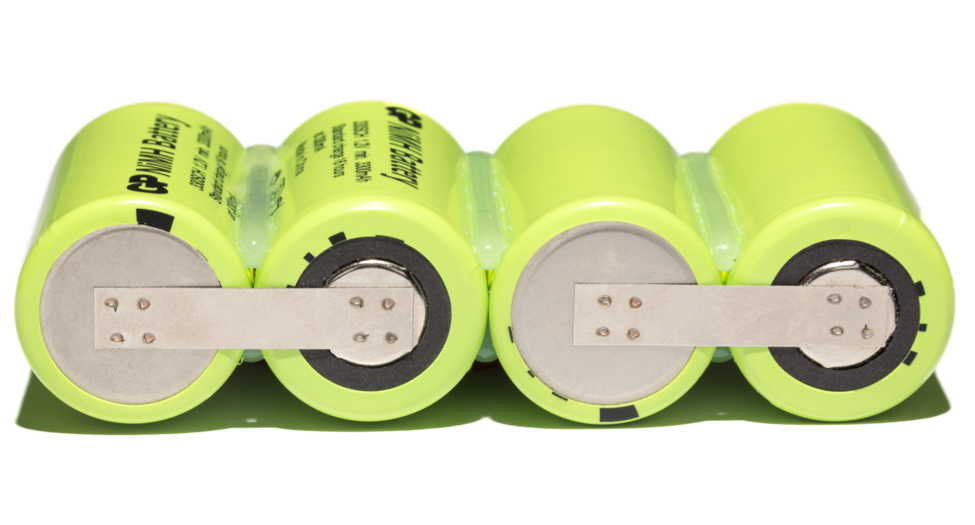

Due to its ability to withstand high temperatures and its conductivity, Nickel is often used as a plating for softer metals and is commonly used to provide hard-wearing plating for components, battery connectors and tags for the electronics industry. Most of the material we provide will be used as battery connectors, to link cells together either as a single tag from cell to cell or as a special etched or stamped tag, which can link multiple cells. The tags can be used as electronic parts, and in resistance to corrosion applications, like handling alkaline solutions and foods.

Nickel plated steel is ideally suited as links for battery connections. This material is both easy to spot weld and solder. Apart from standard coil and plain tags, this Nickel plated steel is often used for H Tags, the industry known 1404 Tag, and PCB board battery tags. Typically, it has 2 microns of nickel plate on both sides. Spot welding is widely used in industries that manufacture solar panels, switches and circuit boards. The spot welding process is ideal for manufacturing complex and delicate electronic components.

Nickel battery connectors, Nickel plated battery connectors and Nickel strip for battery connection are best suited as links for battery packs making it is easy to solder, spot or tag weld.

Datum battery crimps replace slow, expensive soldering processes in battery pack manufacturing. By working with our customers and understanding their processes, we supply our crimps to remove bottlenecks from critical areas of your production lines.

Available wire sizes: 20-26 AWG, Standard 7/0.2mm, others available upon request.

Crimp dimensions: 11mm spade and 16mm in length

Material: Nickel plated stainless steel

Crimps are available in reels of 10,000 pieces per reel.

BATTERY CRIMPS – TYPICAL CHEMICAL COMPOSITION (%)

Fe |

C |

Si |

Mn |

P |

S |

|---|---|---|---|---|---|

| 99.6 | 0.05 | 0.02 | 0.18 | 0.012 | 0.02 |

PURE NICKEL SPECIFICATIONS

Typical chemical composition (%) Nickel 200/201: Ni 99.5 + trace elements

Typical Electrical Resistivity: 9.0 x 10-8 Ω/m

Hardness: 90-120HV

Thicknesses available: 0.127 mm (stock), 0.1 to 0.3mm; all meet industry standard tolerance of 0.01 mm

NICKEL PLATED STEEL SPECIFICATIONS

Typical composition (%): Fe 99.6 + trace elements

Typical Ni plating thickness: 2 µm, both sides

Typical Hardness: 80-110HV

Thicknesses available: 0.127 mm (stock), 0.1 to 0.3mm; all meet industry standard tolerance of 0.01 mm

Datum battery tags are available in nickel-plated steel and commercially pure nickel. All tags are produced at our facility, cut to order with our specialized slitting and cutting equipment. This enables us to deliver high-quality standard and custom-size tags at competitive prices with short lead times.

Most of the material we provide will be used as battery connectors, to link cells together either as a single tag from cell to cell or as a

special etched or stamped tag, which can link multiple cells. Custom tags are becoming increasingly popular as miniaturization and power electronics drive specialized shapes, formats and load requirements. We can specialty etch or stamp custom shaped tags to ensure high-yielding and repeatable production processes.

NICKEL STRIPS & TAGS – TYPICAL CHEMICAL COMPOSITION (%)

Nickel 200/201 |

|

|---|---|

| Ni | 99.5 |

| Cu | 0.001 |

| Fe | 0.07 |

| Mn | 0.25 |

| C | 0.01 |

| Si | 0.14 |

| S | 0.001 |

| Mg | 0.02 |

| Ti | 0.002 |

TYPICAL MECHANICAL PROPERTIES

Nickel 200/201 |

|

|---|---|

| Tensile Strength N/mm2 | Max 130 |

| Tensile Strength N/mm2 | Min 50 |

| Electrical Resistivity Ω/m | 9.0 x 10-8 |

SIZES AVAILABLE

Coils: 3, 3.2, 4, 4.8, 5, 6, 6.35 mm wide

Tags cut to length on request

Stock is 0.127 mm thick; others available upon request

HEAT RESISTANCE

Nickels heat resistant qualities mean it is suitable for use in extreme temperatures such as aircraft engines and power generation facilities.

CORROSION RESISTANCE

Datum Nickel has a high corrosion resistance making it suitable for challenging environments such as offshore installations, chemical plants, fuel refineries and medical equipment.

STRENGH

Our Nickel will maintain high strength and stability under extreme temperature changes.

COST EFFECTIVE

Nickels long-term durability increases product lifecycle reducing replacement costs.

HYGIENIC

The corrosion resistance of Nickel make it easy to clean and sterilize – a superior metal for use in medical environments, the optical industry and food production where hygiene is critical.

Nickel-plated steel tags are an economical alternative to pure nickel. In many cases, they can serve as a drop-in replacement to traditional nickel and deliver a significant cost-savings. We also offer nickel-plated steel battery crimps in a variety of configurations.

Pure (>99.6%) nickel is highly corrosion-resistant and has lower electrical resistance than nickel-plated steel; therefore it is recommended for applications in chemical or food processing, high-performance electrical and electronic assemblies, and other harsh environments. We use only 200 and 201 grade nickel that conforms to the ASTM B162 standard because we feel it has the best combination of mechanical, electrical and chemical properties for this application.

We test all incoming material to assure it meets Datum quality standards before it is stocked, and use specialized equipment to assure repeatable, high-quality output from our wholly owned, ISO 9001:2015 certified production facilities.

Resources

Resources

Visit Datum’s Support Library for a complete list of resources.

VIEW ALL RESOURCESNickel Strips & Tags Datasheet

View Details

Nickel Plated Steel Datasheet

View Details

Battery Crimps Datasheet

View Details